TWI has been involved in underwater welding research for over 25 years for the marine, offshore and oil and gas industries. Consultancy and development work has covered consumables, automated underwater welding, and equipment.

Description

Underwater welding can be divided into three main types:

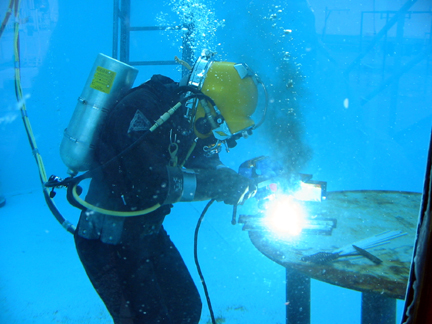

Wet underwater welding, where manual metal arc welding (MMA) is the most common process. Flux-cored arc welding (FCAW) has been widely used in the former Soviet Union . Friction welding, which has the advantage of being relatively insensitive to depth, and which lends itself to robotic operation, has the potential for use in deep water repair.

Coffer dam welding, which is carried out in the dry, in air, where a rigid steel structure to house the welders is sealed against the side of the structure to be welded, and is open to the atmosphere.

Hyperbaric welding, in which a chamber is sealed around the structure to be welded, and is filled with a gas (commonly helium containing 0.5 bar of oxygen) at the prevailing pressure.

Current status

The materials which are most commonly welded are microalloyed C-Mn steels of pipelines and offshore structures, and C-Mn steels on ships and harbour works. Extensive repairs have been carried out to offshore platforms following hurricane or explosion damage. Coffer dam welding is most likely to be employed in harbour works or ship repair, although wet underwater welding is also widely used. Semi-automatic FCAW has been used in the former Soviet Union for repairs to (shallow) pipelines and to the hulls of sunken ships, prior to refloating.

Hyperbaric welding, using MMA (SMA), TIG (GTA) or FCAW, is the preferred process for high integrity welds, particularly for deep water welds, including tie-ins in pipelines and risers in the oil and gas industries.

Important current issues

The technology for hyperbaric welding is well established, and generally well researched. There is, however, a need to be able to use the process at ever greater depths, with research being carried out in the range 500 to 1,000m.

Wet underwater MMA (SMA) welding has now been widely used for many years in the repair of offshore platforms, including those which have suffered hurricane or war damage. Future needs will include the requirement to repair offshore structures in deeper waters, fabricated from higher carbon equivalent steels. In view of the high weld metal diffusible hydrogen levels generated in wet underwater welding, there is a risk of hydrogen-assisted cracking which increases with increasing carbon equivalent. Revised electrode coating formulations and improved power source technology will be required.

Wet underwater FCA welding may find wider use in the west, if it proves capable of giving acceptable weld quality.

Benefits

Underwater welding provides a means of assembly or repair underwater. Alternatives, which include clamped and grouted repairs (which may introduce unacceptably high loading on offshore structures), and the use of bolted flanges for tie-ins, are not necessarily always satisfactory.

Risks

For the humans involved, the risks are of three main types. Firstly there is a potential risk to the welder/diver of electric shock. Precautions include achieving adequate electrical insulation of the welding equipment, shutting off the electricity supply immediately the arc is extinguished, and limiting the open-circuit voltage of MMA (SMA) welding sets. Secondly, hydrogen and oxygen are produced by the arc in wet welding and cutting. Precautions must be taken to avoid the build-up of pockets of gas which are potentially explosive. The other main area of risk is to the life or health of the welder/diver from nitrogen introduced into the bloodstream during exposure to air at increased pressure. Precautions include the provision of an emergency air or gas supply, stand-by divers, and decompression chambers to avoid decompression sickness following saturation diving or too rapid return to the surface from a deep dive.

For the structures being welded by wet underwater welding, inspection following welding may be more difficult than for welds deposited in air. Assuring the integrity of such underwater welds may be more difficult, and there is a risk that defects may remain undetected.

0 komentar:

Posting Komentar